High-voltage power lines, which can transport electricity at voltages exceeding 50,000 volts, often appear bare to the naked eye, a design that puzzles many. The reason behind this is a fascinating blend of physics, engineering practicality, and economics.

Imagine the intricate web of the electrical grid, where High Voltage Insulator components play a critical yet often unseen role. If you've ever looked up at those towering transmission lines, you might have noticed they seem bare, unlike the insulated wires you see at home. This isn't an oversight; it's a deliberate and calculated engineering choice.

The Physics of Insulation and Air Gaps

At the heart of the decision to forgo traditional insulation on high-voltage lines lies a fundamental principle of physics: air is an effective natural insulator. The safety and functionality of power transmission rely on understanding and utilizing this principle.

For ordinary low-voltage applications, like the wiring in your home operating at 220V, a thin layer of rubber or plastic insulation is sufficient to prevent accidental contact and short circuits. However, high-voltage transmission lines operate at vastly different scales, often carrying electricity at 10,000 volts (10 kV) or more, with some critical lines operating at a staggering 500,000 volts (500 kV).

Air's Insulating Properties: Air has a typical breakdown voltage of approximately 3 kV per millimeter. This means it takes about 3,000 volts to create an electrical spark or arc across a one millimeter gap of air. While this provides a baseline, engineers build in massive safety margins.

Maintaining Safe Distances: The power industry meticulously calculates and mandates safe clearance distances. For instance, a 110 kV line theoretically requires a minimum air gap of about 40 millimeters for safety. In reality, these lines are erected dozens of meters above the ground and are positioned meters away from supporting structures and other conductors. This enormous air gap, provided naturally by the environment, acts as a robust, maintenance-free insulating barrier. Attempting to replicate this level of protection with a solid material would be extraordinarily impractical.

This strategic use of air as the primary insulator is a cornerstone of efficient and reliable power transmission, showcasing how engineering often works with natural principles rather than against them. Companies like Huayue specialize in manufacturing the specialized insulators that are used to safely connect these bare conductors to their support structures while maintaining these crucial air gaps.

The Practical and Economic Constraints

While physics makes bare conductors possible, practical and economic realities make them the preferred choice. Adding physical insulation to high-voltage lines introduces a host of significant challenges that impact cost, reliability, and efficiency.

The first major hurdle is weight. A insulation layer thick enough to handle 500 kV would be immensely heavy. This added weight would place enormous stress on support structures and transmission towers. To compensate, utilities would need to build many more, and much stronger, towers at a drastically increased cost.

The second critical issue is heat dissipation. Electrical conductors generate heat under load. Bare overhead lines are excellently cooled by the surrounding air moving freely around them. Encasing them in insulation would trap this heat, leading to potential overheating. This forces the grid operator to derate the line—meaning it must carry less current than a bare wire of the same size to avoid damage, significantly reducing its power transmission capacity and efficiency.

Finally, the cost factor is prohibitive. Manufacturing, transporting, and installing thousands of miles of heavily insulated cable for ultra-high voltages is an extraordinarily expensive endeavor. It's estimated that insulating a 110 kV or higher line could increase costs by at least 3 to 5 times compared to a bare conductor system. This would dramatically reduce the reach of electrical infrastructure investments.

For these reasons, the use of physically insulated cables (e.g., High Voltage Power Composite Insulator technology) is typically reserved for special cases where overhead lines are impossible, such as underground installations, dense urban areas, or submarine crossings. In these scenarios, the insulated cable, often built with a copper core and sophisticated insulation materials, becomes necessary despite its high cost, which can be ten times or more that of an equivalent overhead bare wire system.

Specialized Components and Huayue's Role

The statement that high-voltage lines are "uninsulated" requires a crucial clarification: while the conductor itself is bare, the entire transmission system relies on highly specialized insulation components at critical points. This is where the expertise of companies like Huayue comes into play.

The primary role of insulation is delegated to insulators—distinct, standalone components that serve two vital functions:

They physically connect the live, bare conductor to the grounded transmission tower.

They electrically isolate the conductor from the tower, preventing current from flowing into the structure.

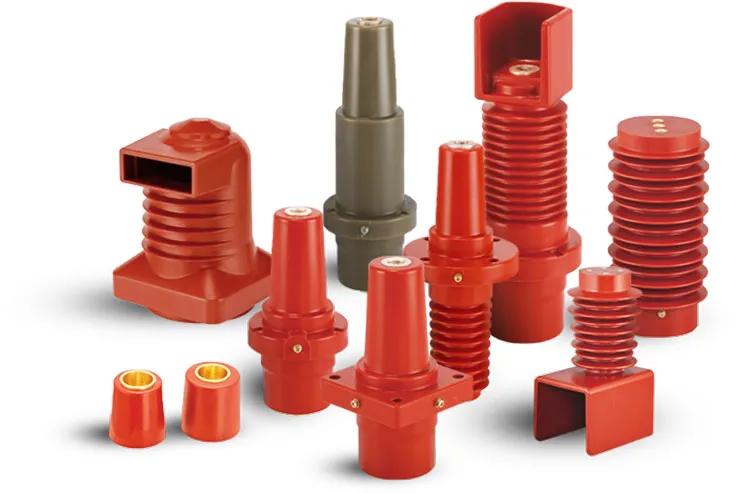

These insulators, such as the U40B/110mm Glass Insulator, are engineering marvels made from materials like tempered glass, porcelain, or composite polymers. They are designed with specific creepage distances (the path along the surface that electricity would have to travel to flash over) and mechanical strength ratings (e.g., 40 kN, 70 kN, 160 kN) to withstand immense electrical and physical stresses.

Huayue, as a professional manufacturer in this field, exemplifies the innovation required. They produce a wide range of insulators, including toughened glass and composite types, for applications from 10 kV to 1000 kV systems. Their product lines include various designs like standard, anti-fog, and aerodynamic profiles, engineered to perform in diverse and harsh environmental conditions.

This approach offers the best of both worlds: the cost-effectiveness and efficiency of a bare conductor for the vast majority of the line's length, combined with the precision-engineered and localized insulation at the points where it is absolutely necessary—the connection to the tower. This system ensures safety, reliability, and economic feasibility for the entire power grid.

High-voltage transmission lines are a testament to pragmatic engineering. They leverage air—a free and abundant natural insulator—to efficiently transport massive amounts of electricity across continents. The use of bare conductors is not a safety compromise but a calculated decision based on physics, practicality, and economics, supported by critical insulation components from experts like Huayue.

Understanding this balance is key to appreciating the complex infrastructure that powers our modern world.

Ready to Specify Your High-Voltage Components?

Whether you're an engineer designing a new transmission route or a procurement specialist looking for reliable suppliers, the choice of components is critical. Explore Huayue's extensive catalog of high-voltage insulators and contact their technical team for customized solutions tailored to your project's specific voltage, environmental, and mechanical requirements. Visit our homepage to learn more about our capabilities and product offerings.

EN

EN