Cable accessories are indispensable connection and protection components in power cable systems, including cable terminals, heat shrink tubing, etc. High-quality insulating materials and advanced manufacturing technology are used to ensure safe connection and reliable operation of cable systems. They are widely used in urban power grids, industrial power distribution, rail transit and other fields, providing reliable connection and protection for power transmission and distribution.

Core products: Terminal heads: cold shrink/heat shrink cable terminals, European/American plug heads (support 1kV~35kV); Intermediate joints: explosion-proof intermediate joint box, heat shrink/prefabricated intermediate connection; Protection: silicone rubber overhead wire insulation sleeve, heat shrink tube (RSG low-temperature flame retardant pipe, RSD composite insulation tape); Branch type: cable branch box shell (adapted to photovoltaic/wind power branch needs).

Normal life: cold shrink / prefabricated: 15~20 years; Heat shrink: 10~12 years.

Factors that shorten life: overload; cable displacement; Chemical corrosion.

Snap-on Type Silicone Overhead Line Cover Bare Wire Insulation Sleeve: low temperature resistance, and can be used continuously under -50C +150C conditions.

Cold Shrink Cable Accessory: provided with special dielectric property, the performance of resistance against tracking and corrosion are strong, special water ab sorption rate

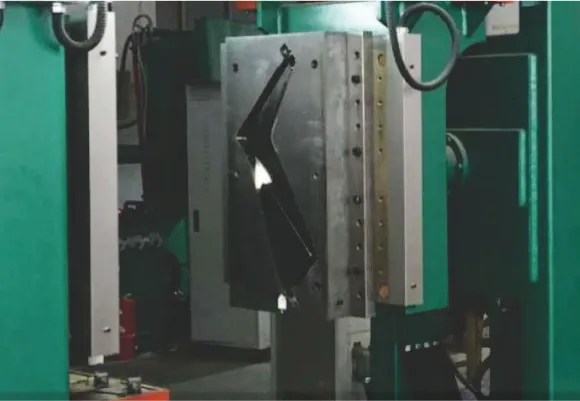

Cable Intermediate Joint Explosion-Proof Box: Indoors or outdoors with harsh environmental conditions (such as cable wells, cable trenches) or outdoors, it is suitable to add internal filling material to the outer casing, and use sealing materials to block both ends.

GET A QUOTE