High Voltage Insulator is key for safe power transmission, but many users wonder: when should it be replaced? Faulty insulators cause outages or safety risks, so learning simple judgment methods (no complex tech skills required) is vital. This article shares easy ways to identify replacement signals.

Inspect the Insulator Surface for Visible Damage

Start with the exterior—visible issues often reveal hidden problems:

Look for cracks or breaks: Even small cracks let moisture, dust, or contaminants seep in, weakening insulation and risking sudden failure. Any cracks or broken parts mean replacement is needed.

Check for abnormal discoloration: Normal insulators have uniform color (white, gray, or brown, based on material). Dark spots, fading, or uneven staining signal material degradation from sun, rain, or pollution.

Remove excessive dirt buildup: Light dust is normal, but thick, sticky deposits (industrial soot, oil, coastal salt) reduce insulation resistance. If dirt can’t be cleaned normally, or if arcing marks (dark burnt spots) appear under it, performance is compromised.

Watch for Abnormal Signs During Operation

Even with a clean surface, operational behavior hints at internal issues:

Listen for unusual noises: A healthy High Voltage Insulator operates quietly. Continuous buzzing, crackling, or hissing during use signals current leakage (partial discharge)—a clear insulation failure sign that risks short circuits.

Track power system anomalies: Frequent unexpected tripping, voltage drops, or unstable current (after ruling out conductor/other equipment issues) likely points to the insulator. This means its insulation capacity is below safe levels.

Consider Service Life and Operating Environment

Insulators have a limited lifespan, shaped by use conditions:

Follow general service life guidelines: Under normal conditions (moderate weather, low pollution, stable voltage), most High Voltage Insulators last 15–20 years. Exceeding this timeframe means regular performance testing and replacement planning, even without visible damage.

Adjust for harsh environments: Tough conditions (high humidity, heavy industrial pollution, coastal salt spray, frequent lightning) speed up aging—lifespan may drop by 30–50%. For example, insulators near factories or oceans may need replacement after 10 years, even if intact.

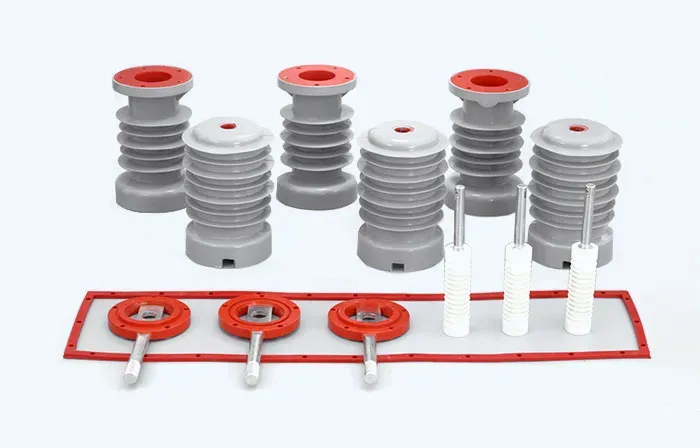

Choose Reliable Replacement to Ensure Safety

When replacement is needed, quality matters. Our company has over a decade of insulation product experience, using durable materials and precision molds to make long-lasting insulators. We also offer technical support to help you pick the right type for your environment. Visit our product page to explore our High Voltage Insulator solutions.

Summary

Judging if a High Voltage Insulator needs replacement is straightforward by focusing on three areas: visible surface damage, abnormal operational signs, and service life plus environment. Timely replacement prevents power disruptions and protects equipment/personnel. These practical steps keep your power system safe and avoid unnecessary risks.

EN

EN