In the complex network of power transmission and distribution systems, insulators stand as unsung heroes that safeguard operational safety and efficiency. These critical components separate energized conductors from grounded structures or other conductors of different potentials, preventing unwanted current leakage and ensuring stable power flow. Whether in high-voltage overhead lines, substations, or industrial equipment, the reliability of insulators directly impacts the overall performance of power systems.

The Core Working Principle of Insulators: More Than Just Non-Conductivity

At first glance, insulators may seem to rely solely on the non-conductive nature of their materials, but their working principle is a synergy of material properties and structural design.

The fundamental mechanism hinges on the inherent non-conductive properties of insulating materials. Unlike conductive materials such as copper or aluminum, insulators are made of substances with extremely high electrical resistance. This resistance blocks the flow of electric current between the energized conductor and the surrounding environment, effectively isolating the circuit and preventing short circuits or ground faults. Insulators must not only withstand normal operating voltages but also transient overvoltages caused by lightning strikes or system fluctuations, without breaking down.

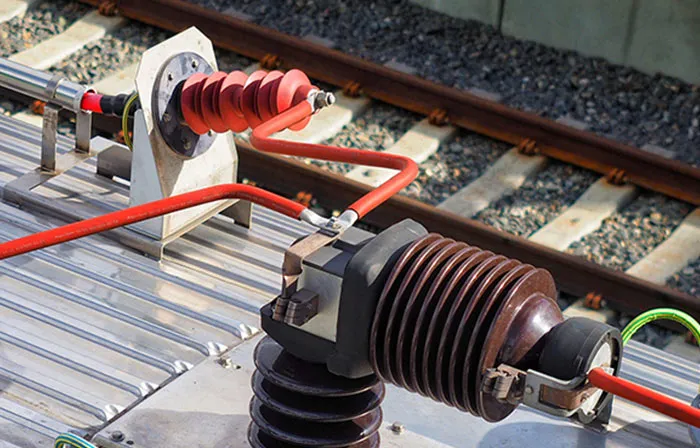

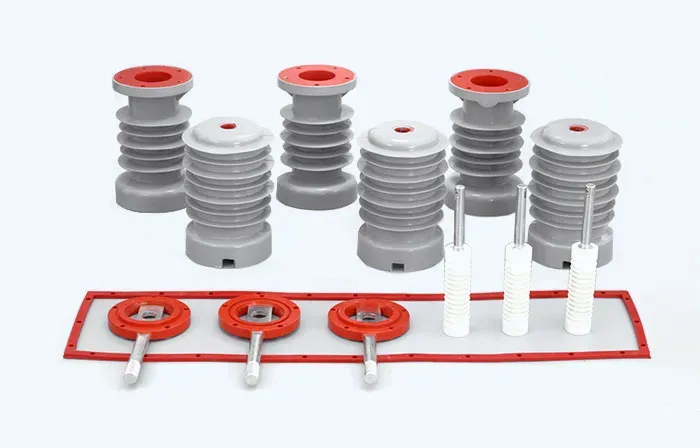

A key structural enhancement that amplifies insulation effectiveness is the shed design. These umbrella-like protrusions extend the “creepage distance” – the path along which current might leak across the insulator’s surface. In humid or polluted environments, rainwater, dust, industrial residues, or salt mist can form thin conductive films on the insulator’s surface. The shed structure disrupts these films, forcing the potential leakage path to follow a longer, more tortuous route. This design significantly reduces the risk of “pollution flashover” and “wet flashover” , two common failures that can disrupt power supply.

Another subtle yet crucial aspect of their working principle is voltage distribution optimization. Insulators are engineered to ensure uniform voltage stress across their surface and interior. This prevents localized high-voltage concentrations that could lead to partial discharge or breakdown, even under long-term operation.

Decisive Conditions for Reliable Insulation Effect

For insulators to maintain consistent insulation performance over their service life, three core conditions are non-negotiable. These factors determine not only their ability to block current but also their durability and adaptability to diverse operating environments.

1. Exceptional Insulation Performance

The primary requirement for any insulator is superior dielectric strength – the ability to withstand high voltages without electrical breakdown. This means the material must resist the formation of conductive paths even when exposed to rated voltages or short-term overvoltages. Insulators must also have low dielectric loss, minimizing energy waste and heat generation during operation. Over time, factors like aging, temperature changes, and chemical exposure should not drastically degrade this insulation capability. For insulators used in harsh electrical environments, resistance to partial discharge is also critical to prolong service life.

2. Sufficient Mechanical Strength

Insulators do more than insulate – they must also support mechanical loads. Conductors, whether in overhead lines or substations, exert significant weight on insulators. Additionally, insulators must withstand external forces such as wind loads, ice and snow accumulation, and mechanical stress during installation or maintenance. A lack of mechanical strength can lead to cracks, fractures, or deformation, which not only compromises insulation but also poses safety hazards . The material and structural design of insulators must balance insulation properties with mechanical robustness, ensuring they can endure both static and dynamic loads over decades of use.

3. Strong Environmental Resistance

Insulators operate in diverse and often harsh environments, so resistance to environmental degradation is a make-or-break condition. They must tolerate extreme temperature fluctuations – from freezing winters to scorching summers – without cracking or losing structural integrity. Ultraviolet (UV) radiation from sunlight can break down some materials over time, so UV resistance is essential for outdoor insulators.

Moreover, insulators must withstand chemical corrosion. Industrial areas expose them to sulfur dioxide, nitrogen oxides, and other pollutants, while coastal regions subject them to salt spray. These substances can erode the insulation material or form conductive deposits, reducing insulation effectiveness. Waterproofing is another key aspect: the insulator’s surface should repel water to prevent the formation of conductive films, complementing the shed structure’s creepage distance advantage.

Why These Conditions Matter for Long-Term System Reliability

Ignoring any of these decisive conditions can lead to costly consequences. A insulator with poor insulation performance may suffer breakdown, causing power outages. Insufficient mechanical strength can result in structural failure, requiring expensive repairs and downtime. Weak environmental resistance shortens service life, increasing replacement frequency and operational costs.

For power system operators and procurement teams, prioritizing these conditions when selecting insulators translates to reduced maintenance costs, fewer service interruptions, and enhanced safety. High-quality insulators that meet these standards not only perform reliably but also adapt to changing environmental and operational demands, delivering long-term value.

Take Action to Secure Your Power System

If you’re seeking insulators that combine robust working mechanisms with uncompromising insulation conditions, it’s time to partner with suppliers who prioritize performance and durability. Whether you need insulators for overhead transmission lines, substations, or industrial applications, focus on products that excel in dielectric strength, mechanical load capacity, and environmental resilience.

Contact Chundexin today to learn more about how premium insulators can elevate your power system’s reliability. Our experts will help you identify the right solutions tailored to your specific operating environment and technical requirements. Don’t let subpar insulators put your system at risk – invest in quality that lasts.

[This article was partially assisted by AI, with human expertise accounting for over 70% of the content – ensuring professional depth and natural expression]

EN

EN