When picking components for power systems, buyers frequently struggle with deciding which material to opt for in their high voltage insulators. The right material directly impacts performance, longevity, and upkeep needs—yet many find it hard to tell apart common options. This article breaks down the core traits of three widely used materials to help you make a smart choice.

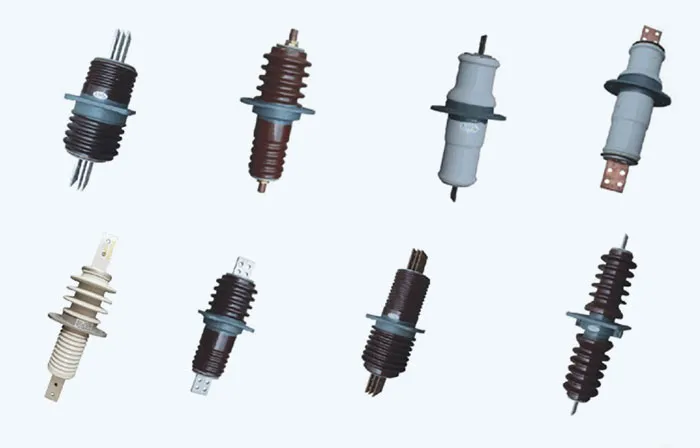

Porcelain (Ceramic) High Voltage Insulators

Porcelain has been employed for decades because of its dependable performance in tough environments. Its greatest strengths are durability and temperature tolerance; it copes with extreme heat and cold without breaking down, making it a solid pick for long-term outdoor use. It also resists chemical damage, which is key in industrial areas or coastal regions where air pollution or salt spray is common.

Porcelain does have clear downsides, though. It is heavy, which pushes up transportation and installation costs—you may need extra hardware or labor to mount it safely. It is also fragile: a strong impact (like from falling branches or equipment) can make it crack or break, leading to unexpected replacement work.

Glass High Voltage Insulators

Glass insulators distinguish themselves with their self-cleaning and simple inspection traits. Rainwater rinses off dirt and dust from their sleek surface, cutting down on the need for manual cleaning—this saves time and upkeep costs over the long run. Another major plus is visibility: if a glass insulator develops internal issues, it often shows obvious signs (like discoloration or cracks) that are easy to spot during regular checks.

The downside of glass is its lower resistance to mechanical shock compared to porcelain. While it handles temperature changes well, a sharp impact (such as from high winds carrying debris) can shatter it. It also tends to be less flexible in design, with fewer customization choices for unique power system setups.

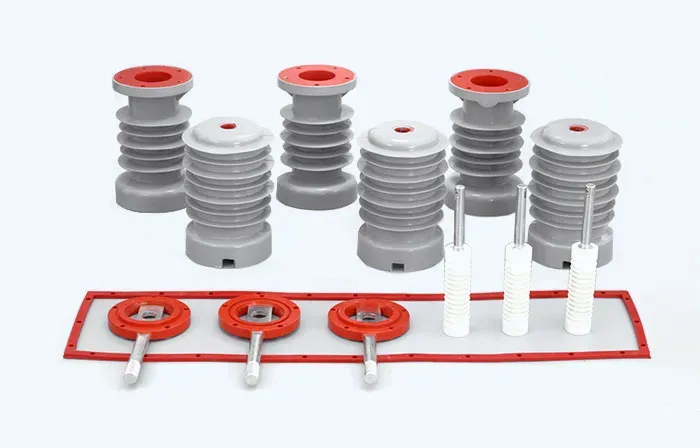

Composite High Voltage Insulators

Composite insulators—typically crafted from fiberglass-reinforced plastic (FRP) with an outer layer of silicone rubber—fix many of the shortcomings of porcelain and glass. The biggest advantage of these insulators is their weight: they are much lighter than both porcelain and glass, which reduces the effort needed for shipping and installation. They are also flexible, meaning they can handle moderate impacts without breaking, and their silicone layer holds up well against UV damage and aging.

Composite insulators do have limits, however. They are less heat-resistant than porcelain or glass; in extremely high-temperature settings (like near industrial furnaces), their performance may drop over time. They also need careful handling during installation to avoid damaging the outer rubber layer—something that could hurt their insulation ability.

How to Choose Based on Your Needs

The ideal material relies on your particular use scenario:

Go for porcelain if you need long-lasting performance in extreme temperatures or corrosive environments.

Choose glass if low upkeep and easy defect detection are your top priorities.

Opt for composite if reducing weight and resisting impacts matter most, and your setup stays away from extreme heat.

If you're looking for High Voltage Insulators that align with your material preferences and system needs, our product page displays options designed for different use cases. Visit our product section to explore detailed specs and find the right match for your project.

EN

EN