Insulation parts (e.g., low-voltage bus bars, insulating supports) are vital for industrial equipment like cranes and shield machines. They isolate electrical components and ensure safe operation. Yet loosening of these parts often causes equipment shutdowns, short circuits, or safety hazards. This article breaks down key reasons for loosening and shares effective prevention methods to keep equipment stable.

Core Causes of Insulation Part Loosening in Industrial Equipment

1.Persistent vibration damages fastening structures

Industrial equipment generates high-frequency vibration. Over time, this vibration causes tiny displacements in fasteners (e.g., bolts) that hold insulation parts. Displacements accumulate, loosening bolts or breaking connections between insulation parts and equipment frames. Loose parts shift, creating gaps that reduce insulation effectiveness and raise electrical fault risks.

2.Improper installation weakens fixing stability

Without torque tools, fasteners may be too loose (easy to vibrate loose) or too tight (causing material deformation later).

Skipping buffer materials (e.g., rubber pads) lets vibration transfer directly to insulation parts, accelerating fastener wear.

3.Material aging and environmental erosion reduce fixing ability

Rubber or plastic insulation supports lose elasticity with age, weakening their grip on fasteners.

Industrial oil, dust, or chemical fumes corrode fasteners and part surfaces, weakening connections and making parts more prone to vibration-induced loosening.

Practical Prevention Strategies for Insulation Part Loosening

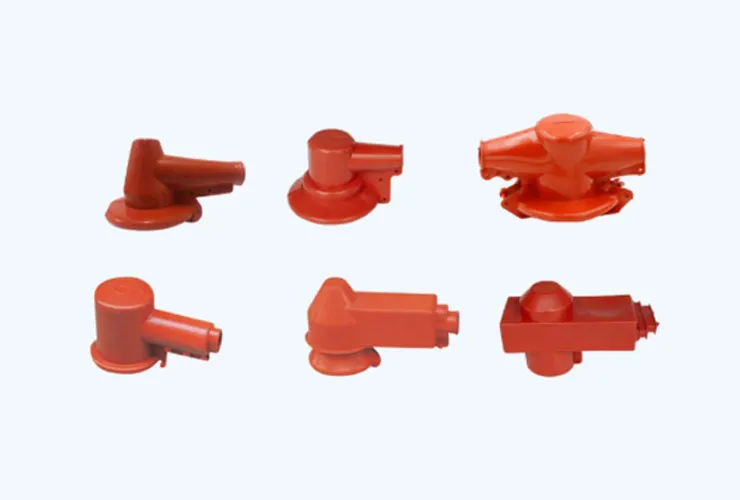

1.Choose anti-vibration designed insulation parts

Opt for parts with reinforced buckle structures or integrated rubber buffers. These designs absorb vibration energy, reduce impact on fasteners, and prevent bolt displacements—keeping parts secure even in high-vibration equipment (e.g., shield machines).

2.Follow standard installation and regular inspections

Use torque tools to tighten fasteners to specified levels; add compatible buffer materials to isolate vibration between insulation parts and equipment frames.

Inspect insulation parts quarterly (more often for high-use equipment). Spot loose bolts, cracked buffers, or corroded components early, and tighten or replace them promptly.

3.Select environment-adapted materials

Pick anti-aging and corrosion-resistant insulation parts. For oil-rich or chemical-heavy environments, choose parts with oil-repellent surfaces or corrosion-resistant coatings. These materials maintain structural integrity longer, ensuring stable fixing systems.

Conclusion

Insulation part loosening in industrial equipment stems from persistent vibration, improper installation, and material aging or environmental erosion. Choosing anti-vibration parts, following standard installation, and selecting environment-adapted materials effectively reduce loosening risks.

To explore insulation solutions for stable industrial equipment operation, visit the product page for detailed technical information and scenario-specific application cases.

EN

EN